EXACTLY FITTING YOUR REQUIREMENTS

LED Industrial luminaires.

LED industrial luminaires in the machine room or at the assembly station have to meet high requirements: colour fidelity, protection classes, voltage, coverage – to name just a few points.

LED luminaires for industry must fit exactly into the structural conditions. And reliably provide high-quality light for a long time. For clear vision at the workplace. Where it is needed.

We make sure of that. With a wide range of LED industrial luminaires that we produce in Germany. According to the highest quality standards. At fair prices. With personal consultation that focuses on your requirements.

Our team will be happy to advise you on all aspects of optimal machine lighting. Do not hesitate to contact us, one of our experts will get in touch with you immediately and work with you to find the optimal solution for your machine lighting.

Benefits to you.

Our range.

- on site for you in over 40 countries – 30 experienced partners

- only in Germany

- 80% of our LED industrial luminaires are available from stock

- State-of-the-art energy efficiency

- Maintenance-free – no need to replace light sources

- LEDs with quality – exclusively from reputable manufacturers

- 60,000 hours guaranteed service life

- Innovative customised solutions

- UL certified LED machine luminaires

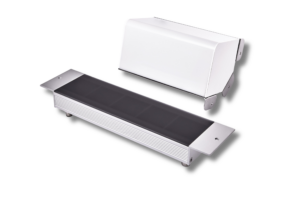

- Compact, recessed, surface-mounted, line and panel luminaires

- Illuminating and signalling

- Rotatable or fixed mounting

- Cover made of toughened safety glass (ESG) or plastic (PMMA)

- Connection via industrial standards (M8/M12)

- Fixed or flexible voltage range

- Dimmable (PWM, analogue)

COMPAKT OVERVIEW

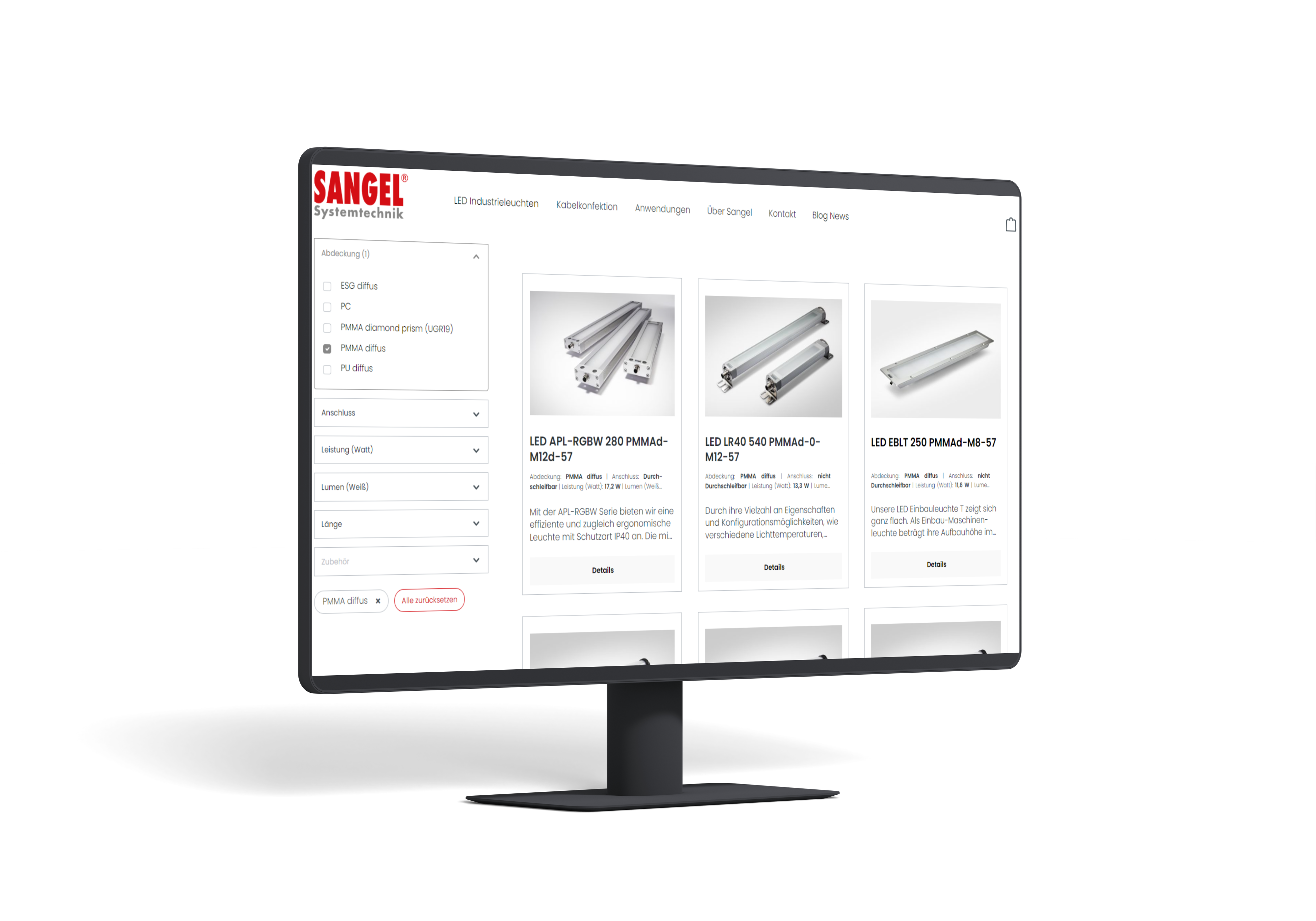

Our LED portfolio.

For everyone who knows what they want.

Quick, simple, specific – find the machine light that suits your needs. Now with a simple filter function.

OUR VALUES

This is what distinguishes us as a manufacturer of LED industrial luminaires.

Top quality

We produce our LED industrial luminaires at our facility in Bielefeld. CE specifications and EMC tests are a matter of course for us. As a manufacturer, we carry out heat and cold tests, mechanical tests and IP and surge tests ourselves. So that you have maximum security in terms of functionality, stability and durability.

Personal consultation

Industrial luminaires for optimum machine lighting or optimum lighting at the assembly station are not changed on a whim. That is clear to everyone. Replacement or modernisation requires structural issues to be sorted out. But other adjustments are also frequently on the agenda. For this, we advise you personally – from the first inquiry to the installation. This will allow your work processes to run smoothly.

Flexible collaboration

We deliver top quality and simultaneously have a wide product range. We do not dread any comparison with our competition. Our consultation also provides you a good price. Many requirements can be met in different ways. Many variations are possible in terms of material and cooperation. We will determine your specific needs and can definitely reach an agreement.

MANUFACTURED TO MEET YOUR REQUIREMENTS

LED customised solutions.

Due to the increasing complexity and the individuality of today’s machines, signaling and lighting are taking up an ever-increasing role of serving as an integrated design component and as a means of optimizing specific processes through the visualization of information.

Though our offerings extensive, standard product do not always fulfill all your mechanical, photometric and interface requirements; therefore, a customized product is sometimes the only possible solution. Why are we the right partner in these cases?

Because of our extensive experience and exposure to the vast projects we have undertaken with our clients to ensure their individual requirements were met with customized and unique solutions, and thanks to the success of these specialized projects, we can now share this experience with you to help you achieve a custom solution quicker and more cost effectively.

ALWAY WELL INFORMED

Our Download centre.

Download the information you require directly.

Whether LED machine luminaires, LED workplace luminaires, LED signal luminaires or LED special solutions as a modification of existing products or completely new developments:

Find out more about our solutions for machine lighting, workplace lighting or signal lights, including mounting sets, connection cables and extension cables.

You will also find the answers to many questions about the technology of LED industrial luminaires in our detailed glossary.

FAQ — LED INDUSTRIAL LUMINAIRES

Frequently asked questions.

Which IP protection classes or IP classification do you have in your range?

The protection class of industrial luminaires is based on the IP classification. This is also referred to as the IP protection class. We offer all common protection classes and can also produce special designs if required. We will be happy to advise you personally. The common IP protection classes for which we receive queries are LED industrial luminaires with IP44, IP54, IP68 and IP69K.

Which protection classes do you offer?

Our 24V LED industrial luminaires have protection class III and are therefore only supplied with protective extra-low voltage. The supply voltage is thus so low that there is no danger from it. In addition to protection class III, there are also protection classes II for “protective insulation” and protection class I for “protective conductors”.

A 24V or 230V LED industrial luminaire: which makes more sense?

LED luminaires with 24V supply voltage are the rule. But 230V LED industrial luminaires are also used. The advantage with 230V: the luminaire has additional power supply. If there is a power failure, the light is still functional.

Which covers are possible for LED industrial luminaires?

Two covers are frequently requested: a plastic cover (PMMA) and tempered glass. The type of cover also depends on the place of use. Fire safety in particular plays a role here.

LED industrial luminaire or LED industrial lamp: is there a difference here?

The term LED industrial luminaire refers to the entire luminaire with all its components. The LED industrial lamp is the illuminant, i.e. the respective lamp that is used. However, the two terms are also sometimes used as synonyms.

LED TECHNOLOGIE

Three advantages of LED technology for industrial luminaires.

1

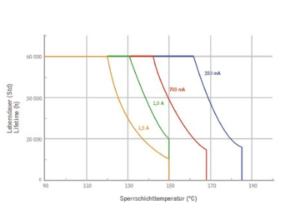

We guarantee a service life of 60,000 hours for our LED luminaires. The service life is considered to have expired as soon as the light intensity drops below 70 percent. The luminaire therefore does not fail immediately, but the luminous intensity decreases. In 3-shift operation over five days per week, we thus guarantee a luminosity of over 70 % for 9.6 years. As a rule, the luminaires thus outlive the system in which they are installed.

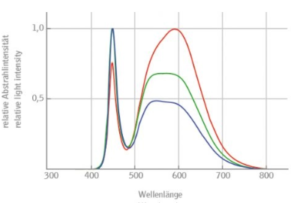

Colour fidelity plays an essential role for a clear view at the point of use. The first question here is whether white or multi-coloured (RGBW luminaires) illumination is required. Colour fidelity is a major advantage of LEDs. Our LED luminaires have good colour rendering, i.e. Ra >80 or CRI >80. The wavelength is in the range between 400nm and 800nm.

2

3

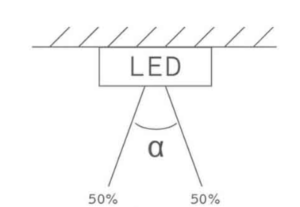

LEDs provide a uniform and flicker-free light. This puts less strain on the eyes. You become fatigued much more slowly. The beam angle is 120 degrees unless otherwise specified. The luminosity is generated via many small LEDs and not just via a single light source. This way, there are far fewer shadows, for example from the hand when performing a work step. This results in fewer errors during the workday.