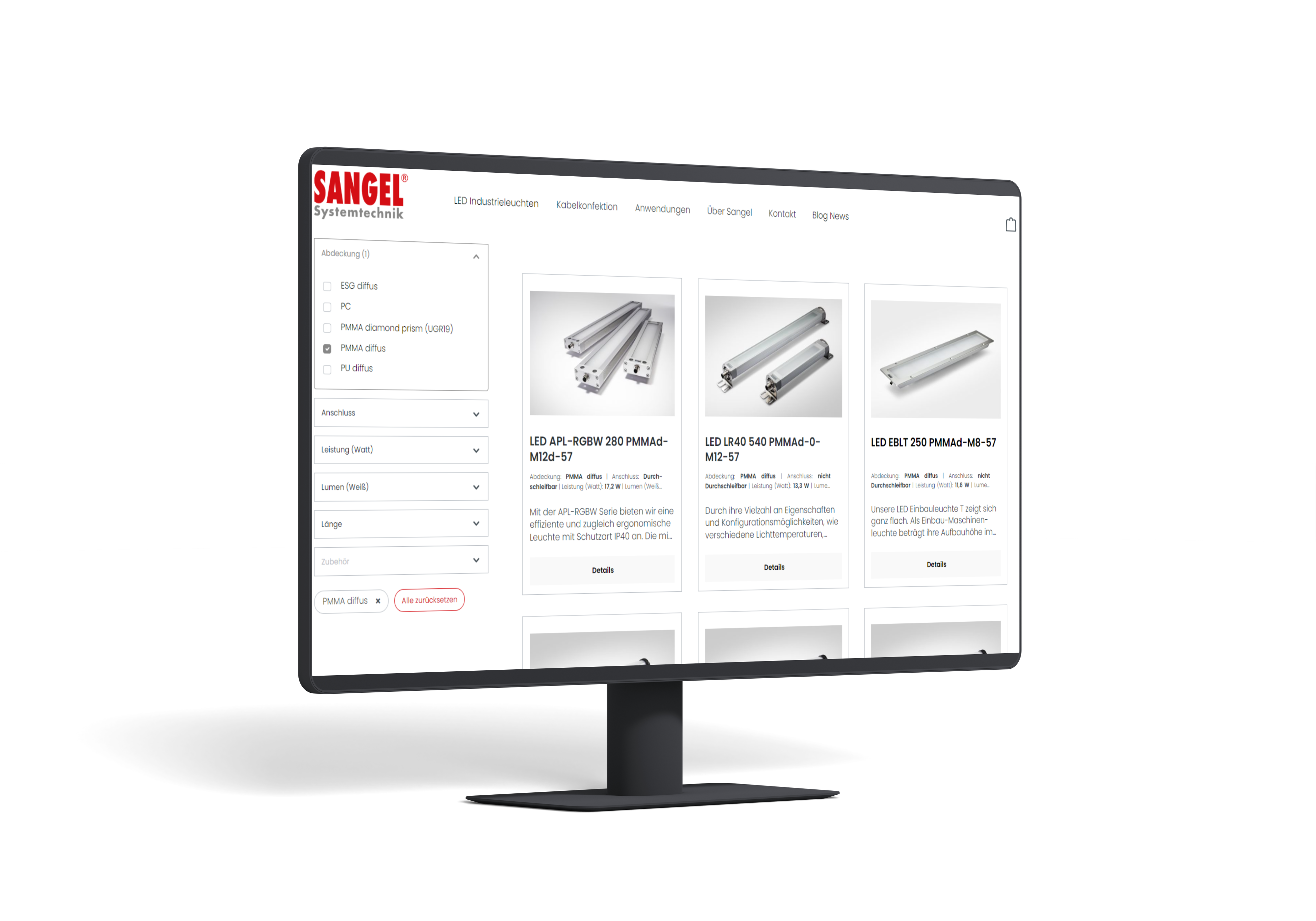

At the SPS 2024 (12-14 November, Nuremberg), the HELUKABEL Group is exhibiting electrical connection technology for all industrial automation sectors. The portfolio includes cables and wires, complete system solutions for energy transmission, and intelligent lighting systems. Visitors can experience the new HELULIGHT Smart Process addressable LED lights at our booth in hall 2, stand 230/231. With these lights, any number of individual machine and system processes can be visualised clearly.

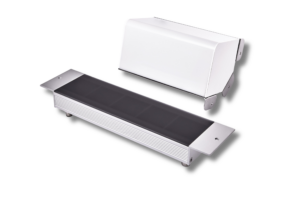

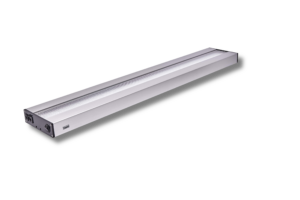

The HELULIGHT Smart Process LEDs being exhibited by the HELUKABEL Group at the SPS are part of an intelligent lighting and signalling system ideal for a wide range of industrial applications. These are individually addressable, RGB LEDs make it possible for different operational parameters such as progress, fill levels, or temperature to be easily monitored visually by machine and systems operators. Thanks to its analogue controls, the HELULIGHT Smart Process is compatible with all common controllers and can be used with virtually all machines, both outside on the housing and inside the machine. This system functions as a standardised and easy-to-implement solution for the visualisation of processes.

Awaiting visitors to the HELUKABEL booth is an extensive assortment of electrical connection technology products. This includes cables, wires, accessories, custom plastic, steel, and stainless-steel drag chains, and pre-assembled and ready-to-use system solutions. The flexible applications of industrial automation and mechanical and plant engineering are in the spotlight.

The HELUKABEL portfolio includes the HELUCHAIN range of drag chain cables, which are specially designed for use in drag chains. A number of variations of these cables are now available with a TPE outer sheath. This plastic material is especially robust and abrasion-resistant, which makes it ideal for extreme mechanical loads and weather conditions. Users have the choice between the HELUCHAIN MULTISPEED 522-TPE control and connection cable, and the HELUCHAIN MULTISPEED 600 single-core cable, all available in both screened and unscreened models. The complete product family is UL certified and is therefore suitable for international use. For all applications not subjected to extreme operating conditions, HELUKABEL has expanded its portfolio to include a number of affordable solutions. With these, we are able to offer our customers better value for their money.

For industrial automation, the HELUKABEL portfolio also includes ROBOFLEX series data and control cables. These cables are designed for use on highly dynamic industrial robots that work in three dimensions. They are able to reliably withstand tension, compression, bending, and torsion equally well. The ROBOFLEX-recycle is also exceptionally resistant to oils and welding beads.

A wide array of data, network, and bus cables are also available, such as HELUKAT copper cables or HELUCOM fibre optic cables, which have proven to exhibit exceptional transmission properties, even in the most demanding of applications. As a competent partner of the drive technology sector, HELUKABEL delivers with motor, encoder, and hybrid cables, as well as accessories, for servo drives. The TOPSERV Hybrid line of PVC and PUR single-cable solutions supports all common digital interfaces such as DSL, EnDat, or EtherCAT.

Planning on visiting us? You can find us at the SPS 2024 in hall 2 at stand 230/231. We look forward to seeing you there!