ALWAYS THE RIGHT CONNECTION

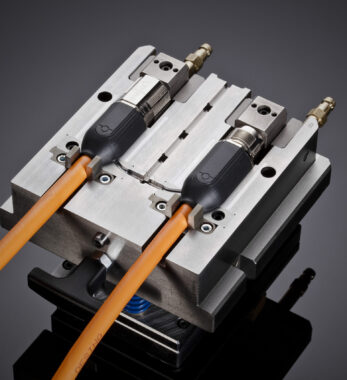

Cable assemblies.

Whether motor or feedback cables, whether data lines via copper or fiber or even your individual cable assembly, we offer the entire bandwidth.

With a high level of automation and smart internal logistics, we are capable to offer you attractive prices along with short delivery times. To achieve this level of service we continuously keep over 1,200 different circular connectors and over 1,000 different cables on stock. At the same time we accept no compromise in terms of quality.

That’s what we are proud of.

Your advantages.

- Crimp force monitoring increases product quality and therefore system availability

- 100% monitoring reduces the risk of failure

- Process data archived – transparency of production history

- Dynamic and static applications

Characteristics.

- DSL, hybrid and conventional systems

- All connector connectors, pole patterns and sizes

- Connectors with quick locking, Locktec or overmoulded types

- All cable types – including customised solutions

- Ribbon contacts and individual contacts possible

WE FIND SOLUTIONS

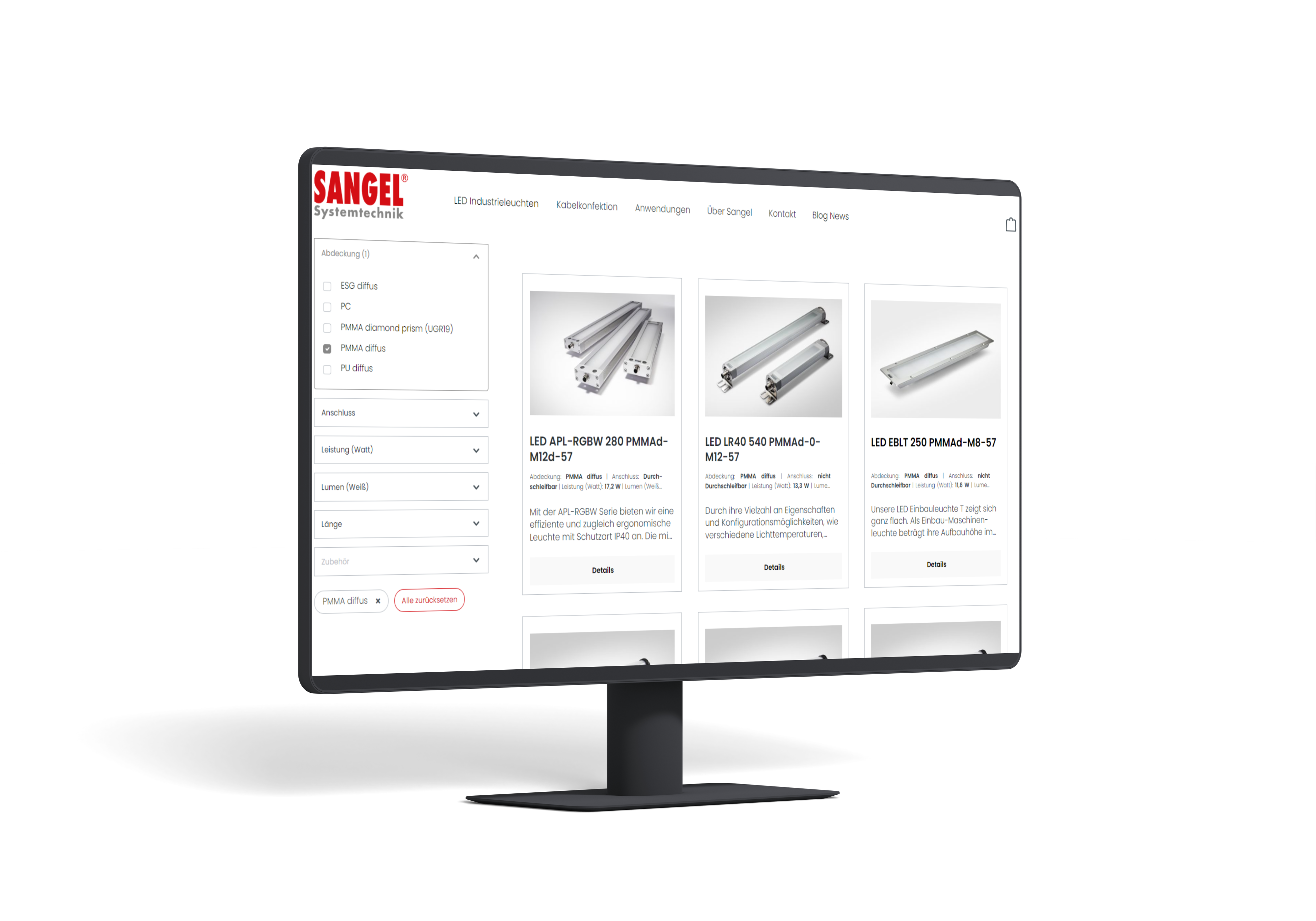

Our Industries.

Industrial automation and drive technology also proves its advantages in medical technology, renewable energy and mobile automation products. We are opening up a much larger market in addition to pure mechanical and plant engineering with these products. This is something we are aware of too, with our understanding of the special requirements of these industries and successfully contributing our experience to numerous projects. We are constantly producing special solutions that we then include in our standard program for you. If you have special requests, just ask.

KNOW HOW CONNECTS

What we connect, lasts. With certificate.

To be able to deliver a highly qualitative product at the right time to the right place for an appropriate price requires a perfect organisation.

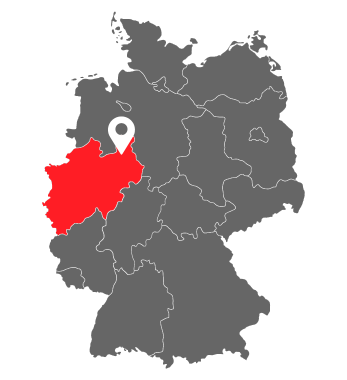

Due to our centralized activities in Bielefeld in which all our processes have been consequently optimized we can achieve highest reliability.

SANGEL® system solutions are strong connections between different components. Strong connections are also generated by memberships, which create close contacts to the machine building field.

DIN ISO 9001:2015.

UL – Wiring Harness.

Membership VDMA.

Membership OWL Maschinenbau.

STAY INFORMED

Our Download Centre.

Download the requested information directly.

Here you can download our current brochures in the areas of drive systems, LED industrial luminaires, Original Equipment Manufacturer and system assemblies, as well as the current delivery and payment conditions and purchasing conditions of SANGEL® Systemtechnik GmbH as pdf documents.