We love problems – yours, for example

Loading crane.

There are many companies who upgrade trucks with mobile cranes resulting in an enormous number of variations in terms of individual customer requirements. These customers require a wide variety of solutions when it comes to weight class, control type, motion sequence and attachment location. To meet these requirements, the cranes have to be custom designed and manufactured.

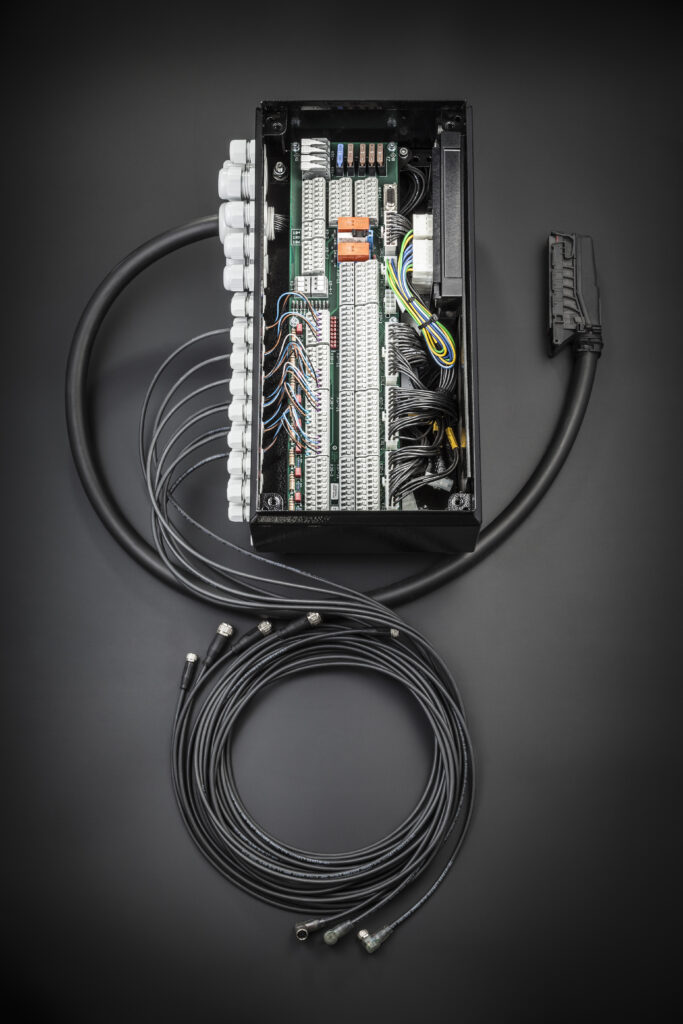

The custom equipment increases manufacturing times and storage costs. Every order has to be examined and analysed in detail. The control units must be custom-built, order picking for individual parts has to be conducted, and the wiring must be done according to the wiring diagram. It is only possible to identify installation errors after successful installation of the control system and the peripherals (sensors and actuators). Commissioning of the vehicle is delayed, and the technology team must implement adjustments under ergonomically unfavourable conditions. Installation on the vehicle takes up to six hours, with much of the time taken up with searching for parts and getting oriented.

The large number of variants is analysed with regard to the control properties to find where there are overlaps. This area of overlap is expanded with common equipment options. Additional installation space is taken into account for the requirements of exotic add-ons. A jumper module takes over the wiring tasks. Variants can be consolidated with a pre-installed housing with populated circuit board and connected cable set. Despite minor additional costs for installed-but-unused options, the savings clearly prevail. The pre-installed and pre-tested control modules are in stock and installed within 90 minutes. The commissioning phase is shortened by 120 minutes on average, because there are fewer delays caused by errors.

STAY INFORMED

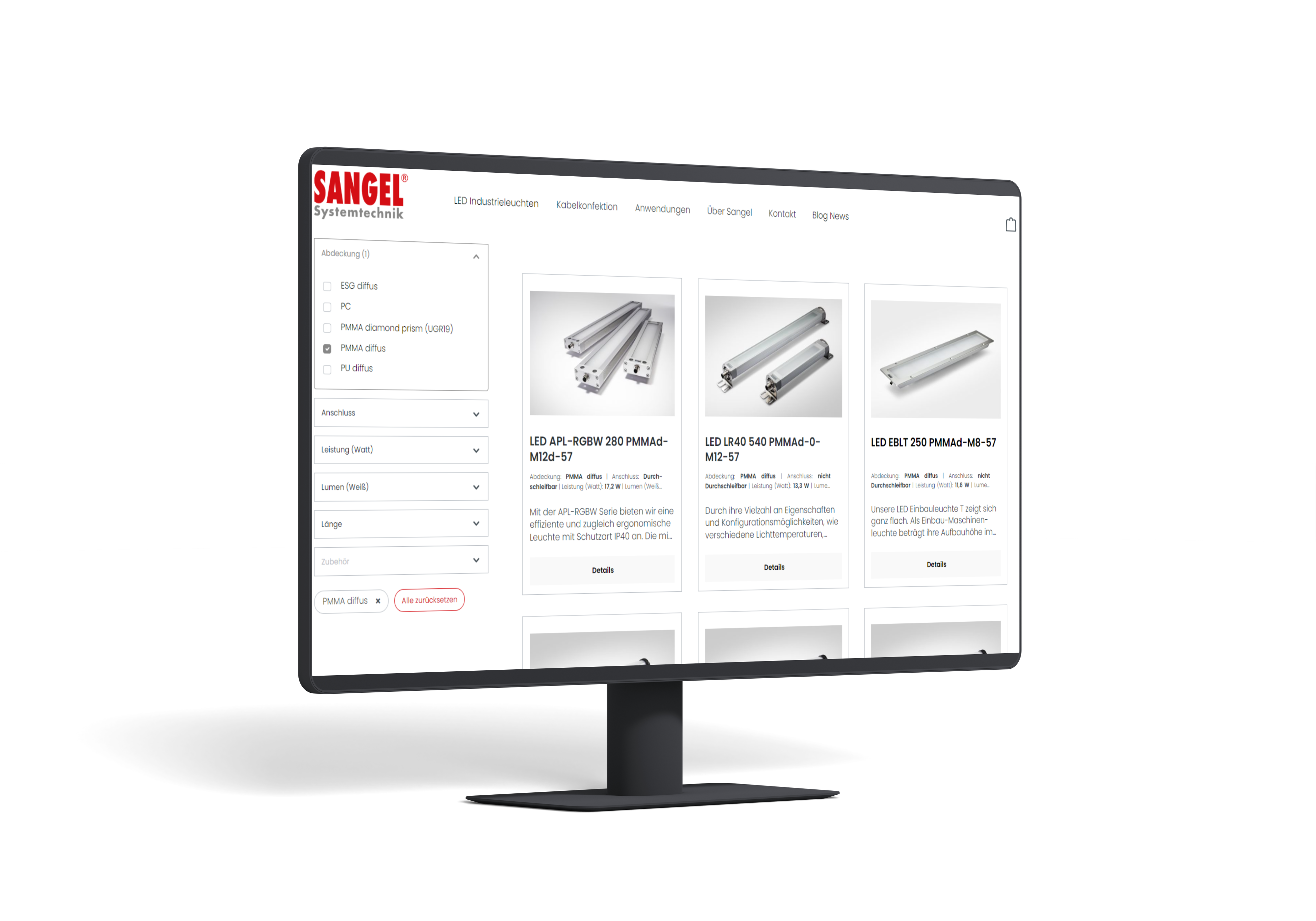

Our Download Centre.

Download the catalogue for your drive system now.

Here you can download our current brochures in the areas of drive systems, LED industrial luminaires, Original Equipment Manufacturer and system assemblies, as well as the current delivery and payment conditions and purchasing conditions of SANGEL® Systemtechnik GmbH as pdf documents. pdf documents.